Collection of Examples of Custom Developments

Pokayoke ToolsWe will manufacture and carefully and promptly deliver our products according to the customer’s request. Here, we will introduce some examples from our many achievements. If you cannot find the product you are looking for or if you would like to customize the product, please contact us here.

- Example 1:Grease Gun

- Example 2:Cable Tie Tool

- Example 3:Grease Pencil

- Example 4:Approval Stamp

- Example 5:Electric Screwdriver

- Example 6:LOCTITE® Hand Pump

- Example 7:TAT Stamp

- Example 8:E-Clip Holder

- Example 9:Torque Screwdriver

- Example 10:Spray Can

- Example 11:Visual Check Process

- Example 12:Calibration of Work Tools

- Example 13:Connector Fitting

- Example 14:Clip Fitting

- Example 15:Feeler Gauge

Example 1Grease Gun

- Customer:

- Agricultural and construction machinery manufacturer

Background of the Request

In the manufacturing process of agricultural machinery manufacturer, there was a problem: "Grease gun was used, but grease was not injected into the required number of places" due to the difference in the number of grease injection points depending on the manufactured items, even though "Whether a grease gun was used" was obtained from the sensor, and pokayoke (mistake proofing) was performed.

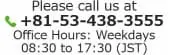

Product Summary

Without modifying the grease gun that the client had been using, we devised a way to detect when the trigger of the grease gun was pulled by installing a Pokayoke transmitter and using a small magnetic switch. Through these technical measures, we were able to achieve pokayoke (mistake proofing) of the grease gun (and ensure the injection of grease into the required number of places).

Example 2Cable Tie Tool

- Customer:

- Automotive parts manufacturer

Background of the Request

We received the following request from an automobile parts manufacturer who bundles wire harnesses using a cable tie tool: "I want to perform pokayoke (mistake-proofing) of the cable tie tool because forgetting to tie INSULOK® (cable ties) has been discovered after shipping".

Product Summary

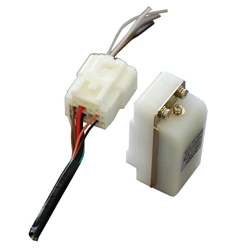

We attached a Pokayoke transmitter to the HellermannTyton cable tie tool MK9 that the customer was using, developed a mechanism to "send a wireless signal when detecting that the excess part of the cable tie has been cut after tying INSULOK®", and realized the pokayoke (mistake-proofing) of cable tie tool. In particular, we created a durable mechanism by adopting a method that did not directly impact the limit switch when detecting cutting.

Cable Tie Tool [EVO7SP] (for narrow ties) Pokayoke Video

Example 3Grease Pencil

- Customer:

- Automotive manufacturer

Background of the Request

We received a request from an automobile manufacturer saying, "We want to perform pokayoke (mistake-proofing) of the marking work by using a grease pencil (a mechanical colored pencil that can write on various materials, such as pottery, metal, glass, rubber, and plastic)".

Product Summary

Considering the characteristics of the grease pencil that the customer was using, we planned to realize the customer's request in a short period of time and at a low cost by newly developing the "barrel part" that matched the grease pencil while using the "main body unit" of the Check Pen S as it was. When designing the "barrel part" by considering both "the length to which the core of the grease pencil could be drawn out" and "the thickness that matched the grease pencil", we devised a way to support pokayoke (mistake-proofing) while maintaining the usability of the grease pencil.

Example 4Approval Stamp

- Customer:

- Automotive manufacturer

Background of the Request

From a fan product assembly factory, we received a request saying, "I want to add the pokayoke (mistake-proofing) function to a large approval stamp to prevent forgetting to press the stamp used at the factory".

Product Summary

Since the shape and mechanism of the large approval stamp were different from the pokayoke (mistake-proofing)-compatible approval stamps developed in the past, we developed a new mechanism to sense stamp operation by combining the movable part of the mechanism and a small limit switch. In addition, by attaching a Pokayoke transmitter to the side of large stamp, we ensured pokayoke (mistake-proofing) without impairing the workability of the large stamp. With these design ideas, we made "counting with the Pokayoke receiver every time a large stamp was pressed down as before" possible.

Example 5Electric Screwdriver

- Customer:

- HERUTU ELECTRONICS CORPORATION

Background of the Request

In the production of products for our own factories, the following improvement proposal was submitted: "After fastening screws at 30 places with an electric screwdriver, we check the number of screws to be fastened in the next process to prevent omission of the screw fastening work. We want to remove this check process".

Product Summary

We attached our newly developed Pokayoke transmitter to the electric screwdriver used in our own production process and developed a mechanism in which "a 'fastening complete' signal is transmitted wirelessly when you fasten a screw with an electric screwdriver". As a result, since the Simple Pokayoke Counter will notify the completion of the work by sound when the electric screwdriver tightens the specified 30 times, workers will come to perform fastening work at 30 places, and the check process is no longer required.

Electric Screwdriver Pokayoke Video

Example 6LOCTITE® Hand Pump

- Customer:

- Industrial machinery manufacturer

Background of the Request

We received a request from an industrial machine manufacturer saying, "In the assembly process of industrial machines, we manually apply the threadlocker to the frequently moving parts of the industrial machine, and we want to prevent omission of threadlocker application".

Product Summary

The LOCTITE® hand pump (threadlocker hand pump applicator) that the customer was using had the feature through which a fixed amount of threadlocker was applied by pulling the trigger "lightly". Moreover, the hand pump itself had the characteristic of being light in weight. By devising a design that took this characteristic into consideration when attaching our Pokayoke transmitter to the LOCTITE® hand pump, the workability of the LOCTITE® hand pump application was maintained, and preventing the omission of thread-locking fluid application was realized.

LOCTITE® Hand Pump Pokayoke Video

Example 7TAT Stamp

- Customer:

- Automotive manufacturer

Background of the Request

We received a request from an automobile manufacturer saying, "I want to prevent omission of installation of special parts by matching the 'number of stampings on the metal part of the engine' and the 'number of special parts dispensed' in a production line (process) that produces multiple products".

Product Summary

Following a request from a customer requiring the application of a "TAT stamp" that could stamp on metal parts, we devised a mechanism to count the number of times the TAT stamp was used. Upon realizing the mechanism, we received another request from the customer saying, "I want to be able to easily replace the TAT stamp, even if it becomes unusable". Therefore, we designed a mechanism by referring to Check Pen S, thereby achieving both workability and ease of maintenance.

TAT Stamp Pokayoke Video

Example 8E-Clip Holder

- Customer:

- MFP unit manufacturer

Background of the Request

From a multifunction device manufacturer, we received a request saying, "We want to prevent omission of E-Clip fitting (E-shaped retaining clip) in the assembly process of the paper feed device (tray module) in a multifunction device".

Product Summary

We realized a mechanism "transmitting a signal when the E-clip is fitted" with the E-clip holder (a tool used for fitting the E-clip) that the customer was using to prevent omission of the E-clip fitting work. To realize the mechanism, we devised a mechanism that could handle different E-clips by changing the "barrel part" according to the shape of the E-clip holder, since "the shape of the E-clip holder differs depending on the size of the E-clip to be handled", and applying the Check Pen S mechanism (composed of the "main body unit" and a "barrel part").

E-Clip Holder Pokayoke Video

Example 9Torque Screwdriver

- Customer:

- Building materials manufacturer

Background of the Request

We received a request from a building materials manufacturer saying, "I want the task count management (pokayoke) of screw tightening work not only for Makita rechargeable screwdrivers but also for manual torque screwdrivers in the production process".

Product Summary

Compared to other tools, since the torque screwdriver needed to detect the completion of work in a very short time, we devised a mechanism to accurately detect the completion of torque screwdriver's tightening work by modifying the Pokayoke transmitter for the torque screwdriver. In addition, since the customer had already installed our Pokayoke receiver on the same production line for task count management of screw fastening work, it was possible to introduce the task count management of a torque screwdriver on site in a short period of time by using the same receiver.

Torque Screwdriver Pokayoke Video

Example 10Spray Can

- Customer:

- Automobile manufacturer

Background of the Request

We received a request from an automobile manufacturer saying, "We want to prevent omission of wax injection (rust preventive) with a spray can during the car body assembly process".

Product Summary

By attaching a commercially available spray can handle (a gun-shaped tool that sprays when the trigger is pulled) to the spray can used by the customer to inject wax into the car body, we realized a mechanism to count the number of times the trigger was pulled by combining our Pokayoke transmitter and the spray can handle. In considering the mechanism, assuming application to various spray cans used at manufacturing sites, we came up with an attachable mechanism without processing the main body of the spray can handle.

Spray Can Pokayoke Video

Example 11Visual Check Process

- Customer:

- Automobile manufacturer

Background of the Request

We received a request from an automobile manufacturer saying, "I want to prevent omission (pokayoke) of visual checks by workers as part of the visual inspection process of automotive glass marking".

Product Summary

In order to be able to confirm that the visual check of the glass marking was performed definitely, we developed a mechanism to "wirelessly transmit the work results when the glass marking was checked (contacted with the glass) with a pen that did not adhere ink". In developing the mechanism, we diverted the mechanism of the Check Pen S so that the pen could communicate with the TW-800 series Pokayoke receivers already in use at the customer's production site. Additionally, we came up with a structure that allowed the pen to be hung from the worker's neck so that visual check work could be performed easily.

Example 12Calibration of Work Tools

- Customer:

- Automobile manufacturer

Background of the Request

From an automobile manufacturer who used a torque wrench to prevent omission (pokayoke) of fastening work in the assembly process, we received a request saying, "I want to create a mechanism to notify the time to calibrate to prevent omission of work tool calibration".

Product Summary

To realize the customer's request at a low cost and in a short period of time, by utilizing existing Pokayoke products (Pokayoke receivers and work tools, such as Pokayoke transmitter-equipped torque wrenches) that customers were using and by connecting a task count display device that managed calibration timing to the Pokayoke receiver, we realized a mechanism "possible to grasp whether the number of times the work tool has been fastened has reached the number of times for the required calibration".

Example 13Connector Fitting

- Customer:

- Automotive parts manufacturer

Background of the Request

We received a request from an automobile parts manufacturer saying, "I want to prevent incomplete locking when fitting wire harness connectors".

Product Summary

To meet the needs of our customer, we developed a dedicated "connector fitting checker" tool to check whether the mutual connectors of wire harnesses used in the customer's production process were in a locked state. Additionally, by attaching a Pokayoke transmitter to the connector fitting checker, we developed a mechanism to "wirelessly transmit the work results when it is confirmed that the mutual connectors are in a locked state". We also realized the size that the connector fitting checker fits in one's hand so that confirmation work can be easily performed.

Connector Fitting Pokayoke Video

Example 14Clip Fitting

- Customer:

- Automotive parts manufacturer

Background of the Request

We received a request from a plastic manufacturer saying, "There is a production process in which clips are fitted into molded plastic products using a hand press machine, and I want to pokayoke (to prevent omission in fitting) the clip fitting work".

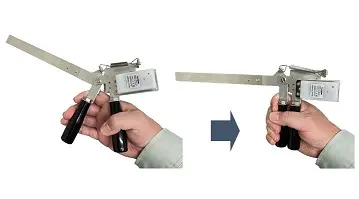

Product Summary

The hand press machine was equipped with a clip tool for fitting the clip, and by creating a mechanism of "wireless transmission at the time of the clip tool being pressed", we realized the task count management of the clip fitting work. To realize this mechanism, which involves diverting the Check Pen S mechanism (a combination of the main body unit and barrel part), we developed a dedicated tool that could be attached to a hand press machine by manufacturing a "barrel part" that matched the shape of the clip tool and by adjusting the spring of the "main body unit".

Example 15Feeler Gauge

- Customer:

- Agricultural machinery manufacturer

Background of the Request

We received a request from an agricultural machinery manufacturer saying, "I want to prevent omission (pokayoke) of clearance checks using feeler gauges in the assembly process of agricultural machinery".

Product Summary

To meet the needs of our customer, we developed a dedicated "clearance checker" tool that wirelessly transmitted instances when the result of the clearance check using the feeler gauge was OK. By creating a mechanism through which "the feeler gauge is inserted into the clearance when you grasp the grip part of the clearance checker", it was possible to detect whether the clearance was within the standard. Additionally, the feeler gauge had a replaceable structure to accommodate gaps of different thicknesses. The clearance checker could communicate with the Pokayoke receiver used at the customer's production site.

Catalogs

Please feel free to contact us regarding product inquiries, opinions, or requests.

Contact Us via Email